Objective:

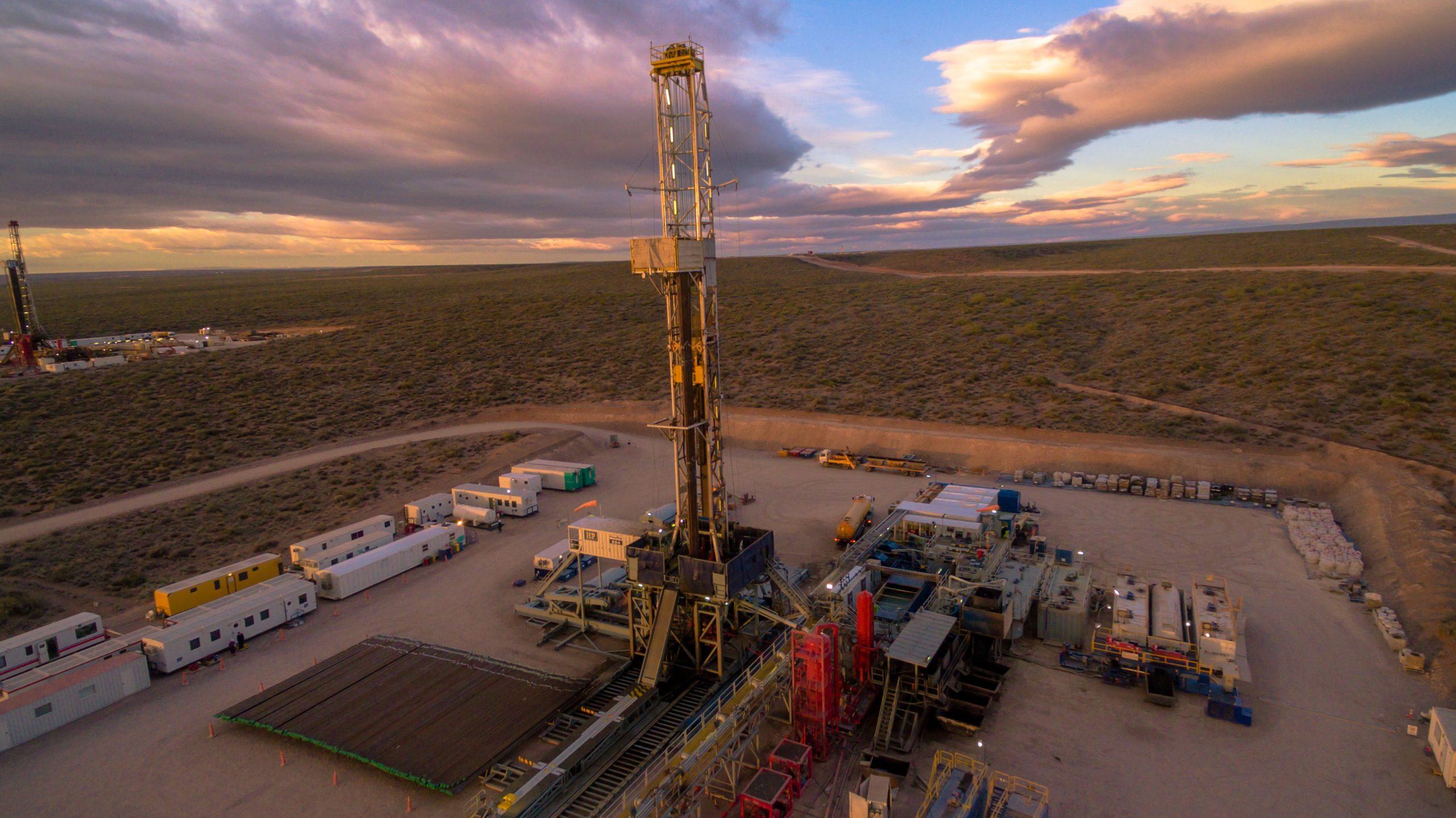

This course aims to provide participants with a comprehensive understanding of drilling extended-reach and horizontal wells, emphasizing wellbore trajectory, torque-and-drag management, hydraulics, and performance optimization to maximize well quality and productivity.

Audience:

Ideal for drilling and completion engineers, drilling supervisors, technical support and subsurface teams, and project managers involved in designing or managing complex directional and extended-reach well campaigns.

Methodology:

Delivered live online, the course blends conceptual lectures with real-world exercises, case discussions, and analysis of operational challenges. Attendees engage interactively to consolidate knowledge.

Scope:

It covers the integrated planning, design, and operational techniques for drilling high-angle or extended-reach wells—addressing challenges like hole cleaning, Equivalent Circulating Density (ECD), Well Path control, and minimizing mechanical complications.

Contenido:

1. Introduction to Horizontal and Extended-Reach Drilling (ERD)

Definition and classification of extended-reach and complex wells

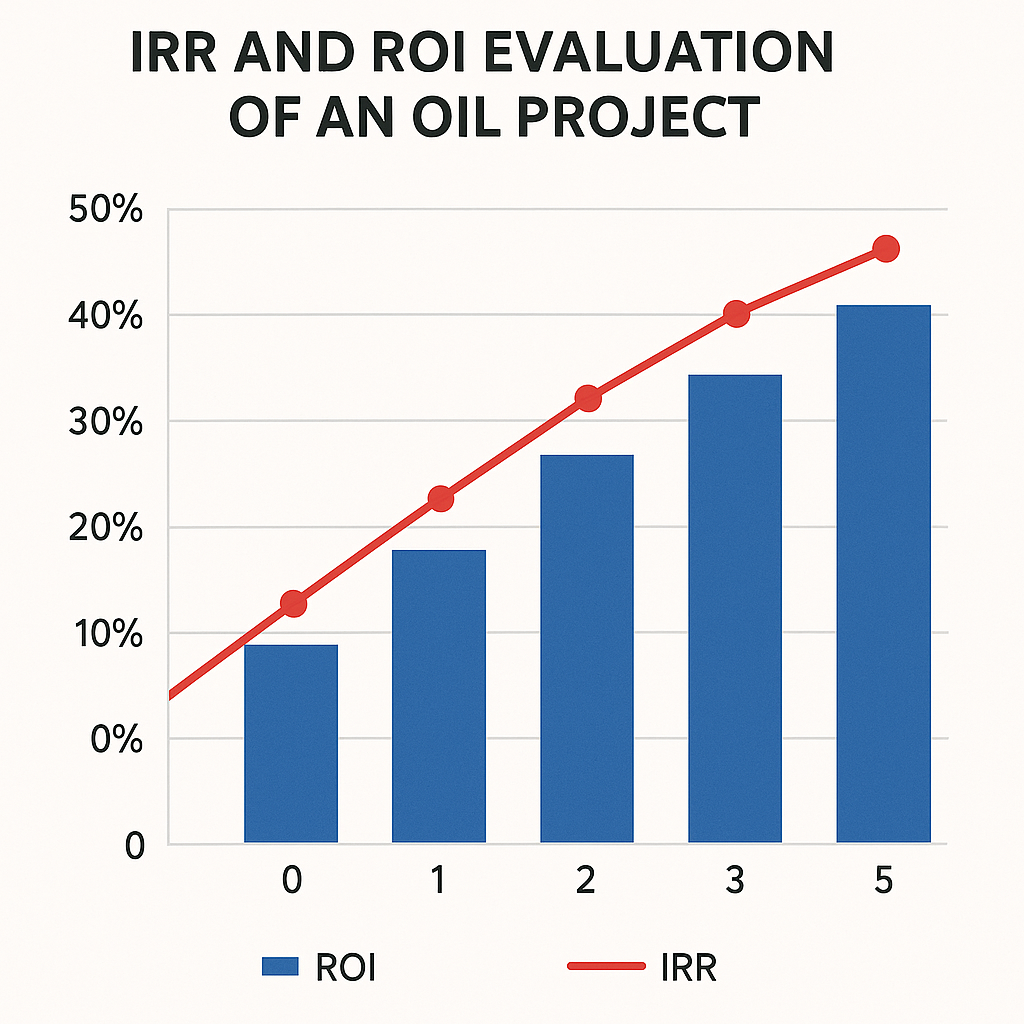

Technical and economic benefits of ERD

Operational challenges and planning requirements

2. Well Design for High-Angle and ERD Wells

Well trajectory design and planning

Tortuosity and build/drop rate management

Casing and completion design considerations

3. Torque and Drag Analysis

Fundamentals of torque and drag

Software applications and models

Buckling and mechanical limitations

4. Hydraulics and Hole Cleaning Optimization

Pressure loss calculations

ECD (Equivalent Circulating Density) management

Cuttings transport and cleaning efficiency in deviated wells

5. Drilling Fluids and Hole Stability

Selection of appropriate mud systems for ERD

Shale inhibition and borehole stability

Fluid rheology and friction factor control

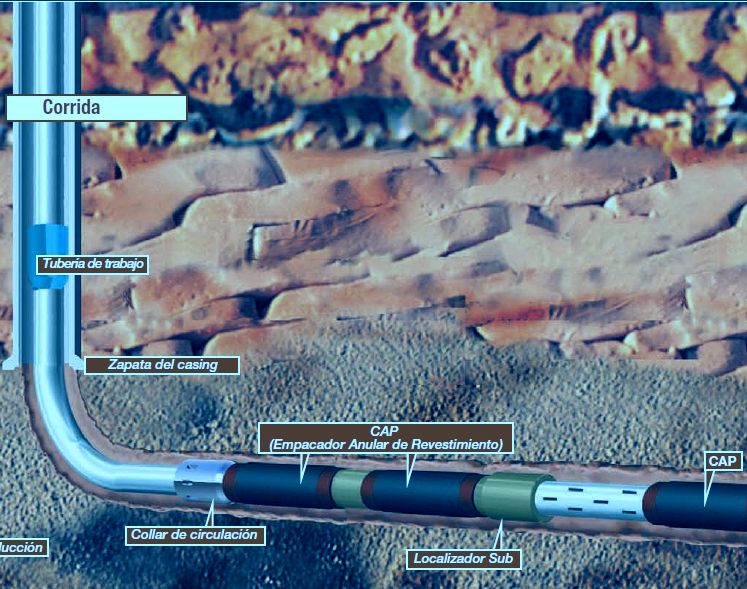

6. Casing and Liner Running in Complex Trajectories

Best practices for casing/liner installation

Mitigating drag and mechanical risks during running

Centralization and cementing strategies

7. Drilling Equipment and Bottom Hole Assembly (BHA) Optimization

BHA configurations for directional control

Rotary steerable systems and performance benefits

MWD/LWD technologies in ERD wells

8. Real-Time Monitoring and Operational Execution

Surveillance and control strategies during execution

Use of digital dashboards and decision-support tools

Managing operational deviations and risk mitigation

9. Lessons Learned and Best Practices

Case studies of successful ERD projects

Common pitfalls and troubleshooting

Summary of key learnings and performance indicators