Objectives:

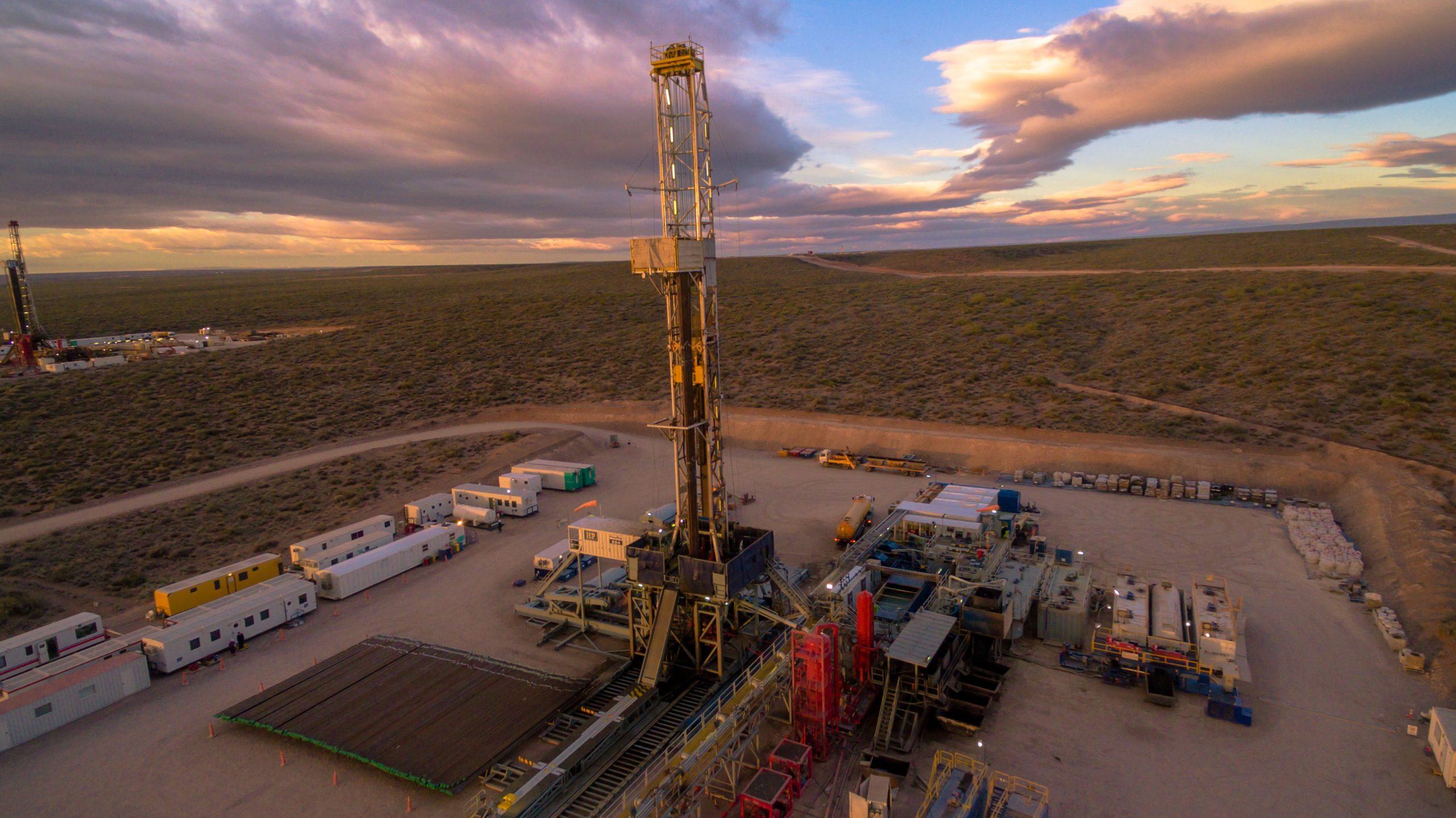

This course aims to provide participants with a comprehensive understanding of horizontal and extended reach drilling (ERD) operations. It focuses on well planning, trajectory optimization, borehole stability, torque and drag management, and risk mitigation strategies. By the end of the course, participants will be able to analyze and optimize ERD well performance, applying both engineering principles and field-proven practices.

Audience:

A Senior drilling engineer, well site supervisor, tool pusher, rig manager and field support personnel. A senior geo-scientist or reservoir engineer looking to get better value from your interactions with the drilling team. Anyone involved with improving drilling performance and cutting drilling costs.

Methodology:

The course is delivered through a blend of theoretical lectures, practical problem-solving sessions, group discussions, and case studies. Real-world data and field scenarios are used to simulate planning and execution challenges, encouraging interactive learning. Participants are guided through technical tools and strategies that can be applied immediately in their professional environments.

Scope:

Participants will gain a deep understanding of the engineering, operational, and logistical aspects of horizontal and ERD wells. The course covers advanced well design, risk management, mechanical considerations, and performance optimization techniques. The goal is to equip professionals with the skills to reduce drilling time, prevent operational issues, and ensure well integrity throughout the well’s lifecycle.

Course Program:

- How increasing hole angle creates significant problems and NPT because of Hole Cleaning, we look at how to identify, address and mitigate these problems.

- The origins of Torque and Drag in the well bore and how they impact our ability to increase our drilling radius from any rig. Why drag impacts horizontal lateral lengths. Drag model types, use and limitations of these models.

- Delivering world beating high angle and ERD wells with limited rig capabilities.

- Operational practices for connections, tripping and managing BHP within fracture limits.

- How to monitor the well condition and how to interpret the data we collect to get the correct understanding of changes happening in the well.

- Well control issues in high angle and horizontal wells.

- Managing drilling risks

- Impact of wellbore stability on drilling efficiency

- Well bore monitoring as a tool of optimised drilling

- Drilling Risks: controllable factors and factors which constrain

- Limits on wellbore strength and the issues of losses, ECD,swab and surge pressures. Managing these issues with UBD and MPD technologies.

- Offset Well Selection: relevant data, data organization, and stick plot

- Risk analysis, time breakdown and understanding the drilling operation as a process

- SMART instructions and RACI control of the drilling process

- Key Performance Indicators (KPI) how to define these and work with them

- Benchmarking drilling performance against nested KPI’s

- Technical Limit Identification and use.

- Task breakdown analysis and its use in optimisation of drilling

- Building continuous improvement, learning systems in drilling improvement

- The creation and use of the risk register and drilling roadmap

- Human factors and the importance of controlling ‘soft’ issues in drilling teams

- How to design the Bottom Hole Assembly (BHA) for low angle wells and how this fundamental design must change as the well inclination increases. This will include a look at jarring and jar placement in high angle BHA’s

- Geomechanics principles and how they can be applied to high angle wells.

- How the tendency of the Bottom Hole assembly to build, drop or hold angle must be designed to match the desires well profile and how this is achieved to deliver wells with the lowest tortuosity. How tortuosity adversely affects modelling of T&D.

- The evolution of directional drilling technology, the key drivers for this and why so many wells are now drilled with high cost rotary steering tools in ERD wells.

- Surveying the well, the key technologies used to survey the well and how mistakes in well positioning are made. Making sure that the uncertainties and errors in the ERD project are minimised. Survey reprocessing techniques to improve accuracy of placement.

- Formation evaluation tools as a drilling engineering resource and how to use this data to show wellbore quality.

- Shock and Vibration of the downhole equipment, its origins, its impact and how to reduce or remove this unwanted problem, reduce NPT and improve performance.