Objectives:

The course aims to equip participants with the knowledge to evaluate, design, and implement chemical EOR strategies—including polymer flooding, surfactant injection, and alkaline methods. Emphasis is placed on selecting appropriate chemicals, understanding reservoir conditions, and optimizing recovery performance.

Audience:

The course is designed for reservoir engineers, production engineers, EOR specialists, project managers, and technical professionals involved in field development planning, chemical injection programs, or optimization of mature fields.

Methodology:

Delivered through online live sessions, the course combines theoretical instruction with interactive discussions and field case studies. Concepts are reinforced via practical examples and simulation-based analysis to ensure applicability in real operational contexts.

Scope:

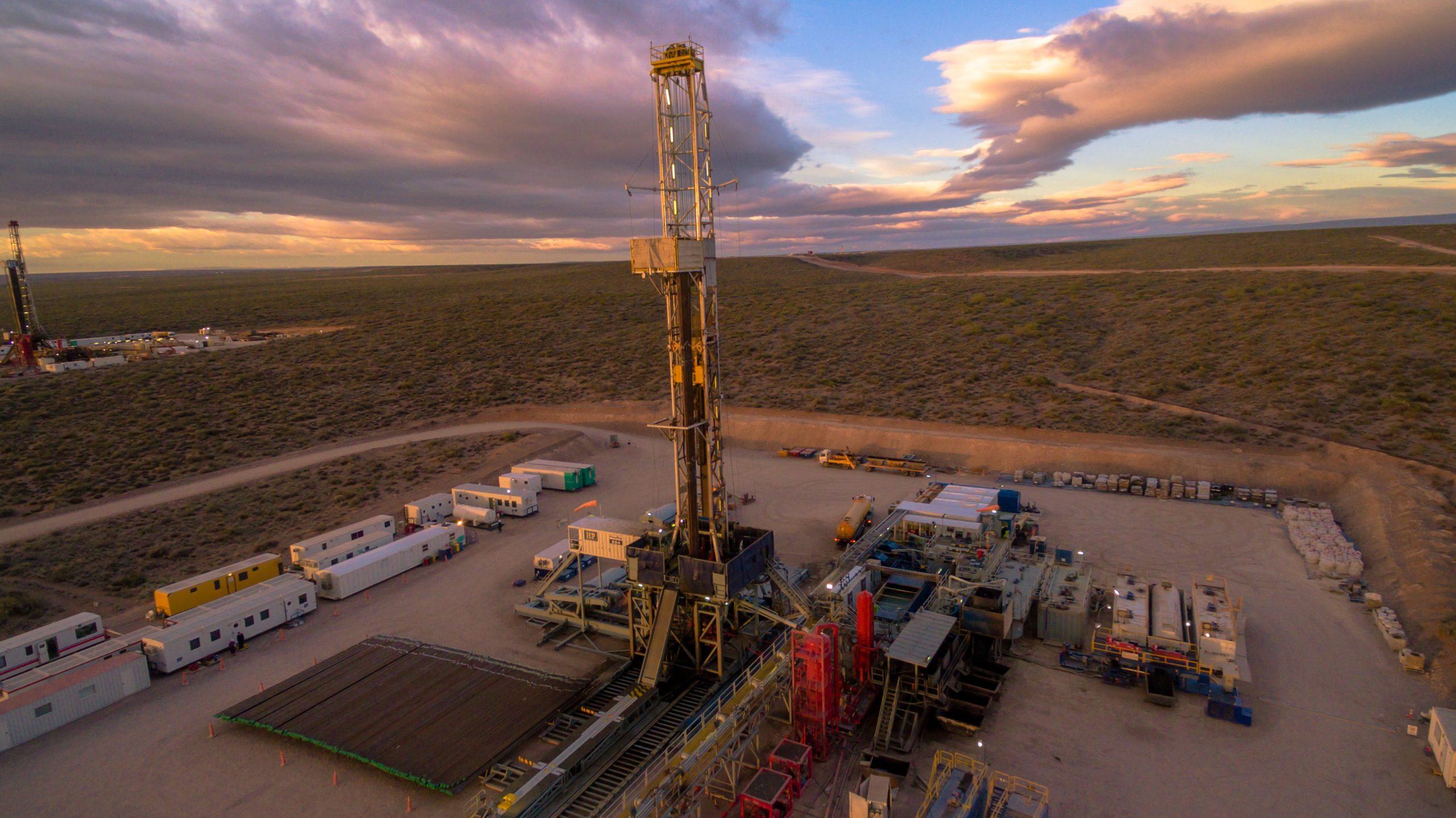

This course provides a comprehensive understanding of chemical enhanced oil recovery (EOR) methods, focusing on their theoretical background, chemical formulations, mechanisms, and field applications. It bridges the gap between laboratory research and real-world implementation, tailored to both sandstone and carbonate reservoirs.

Course Program:

1. Introduction to Chemical EOR

- Overview of EOR methods

- Role of chemical EOR in oilfield development

- Advantages and challenges of chemical flooding

2. Fundamentals of Chemical EOR Mechanisms

- Rock-fluid interactions

- Wettability alteration and interfacial tension reduction

- Mobility control and sweep efficiency

3. Polymer Flooding

- Polymer types and selection criteria

- Rheology and viscosity optimization

- Polymer degradation, retention, and injectivity

4. Surfactant and Alkaline Flooding

- Surfactant types, micelle formation, and phase behavior

- Alkaline flooding principles and soap generation

- ASP (Alkaline-Surfactant-Polymer) formulations

5. Chemical EOR Screening and Design

- Reservoir and fluid criteria

- Laboratory testing and simulation input

- Pilot testing and full-field implementation

6. Field Case Studies and Lessons Learned

- Examples from sandstone and carbonate reservoirs

- Operational considerations and production monitoring

- Cost analysis and risk mitigation

7. Environmental and Economic Aspects

- Handling of produced fluids

- Impact on facilities and surface operations

- Economic feasibility and project evaluation