Objectives:

This course aims to provide participants with a comprehensive understanding of geothermal drilling operations, including planning, design, challenges, and operational procedures. It focuses on the differences between geothermal and conventional drilling, emphasizing high-temperature considerations, fluid management, and borehole stability.

Audience:

The course is intended for drilling engineers, geothermal project managers, field supervisors, and professionals involved in the planning and execution of geothermal wells. It is also suitable for those transitioning from oil and gas to renewable energy sectors.

Methodology:

The course combines instructor-led lectures, real-world case studies, and interactive group discussions. Participants will analyze technical scenarios and review geothermal-specific drilling strategies to ensure practical understanding and application of the course material.

Scope:

It covers the fundamental and advanced aspects of geothermal well construction, addressing well design, materials selection, drilling fluids, lost circulation, and completion strategies. Participants will gain insights into the specific thermal and geological challenges of geothermal fields.

Course Program:

1. Introduction to Geothermal Drilling

- Key definitions and concepts

- Types of geothermal wells

- Comparison with oil & gas wells

- Geothermal heat sources and types of exploitation

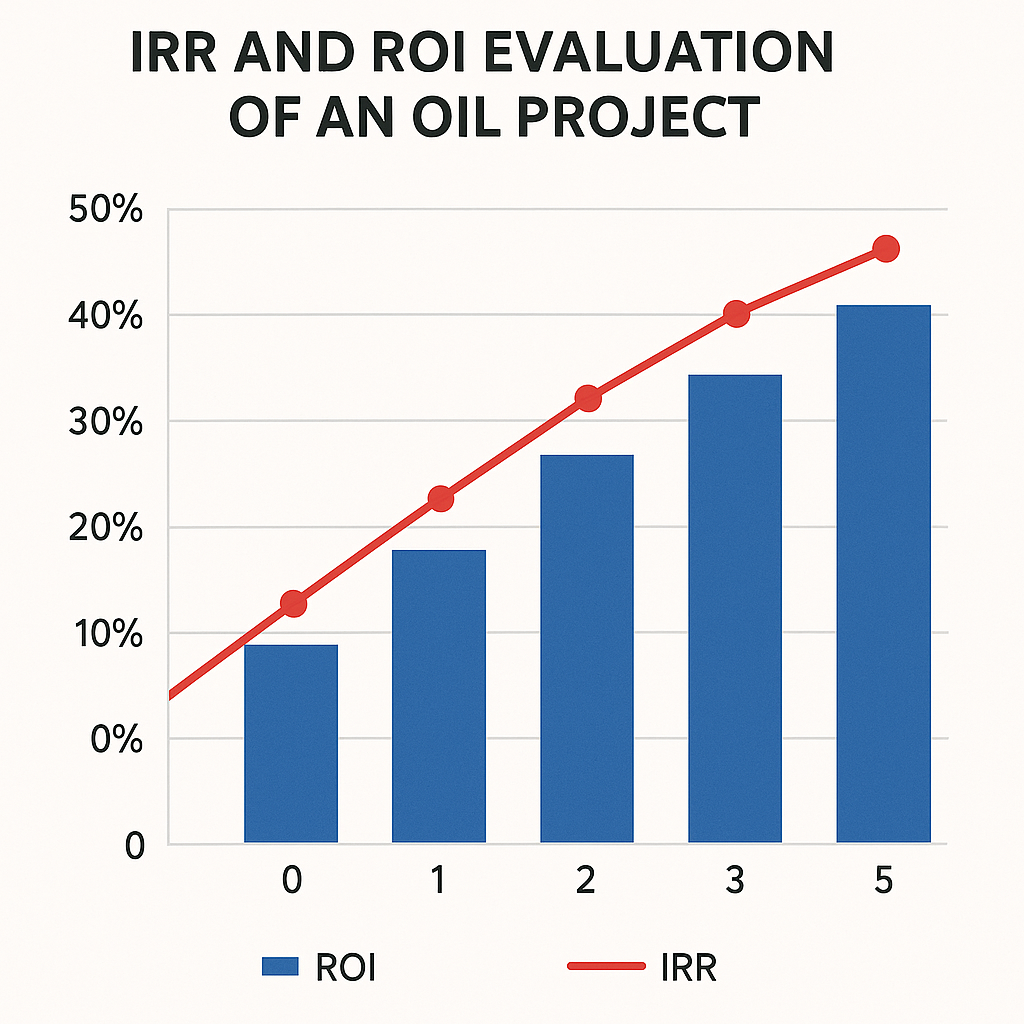

- Performance gaps and how to evaluate a geothermal resource

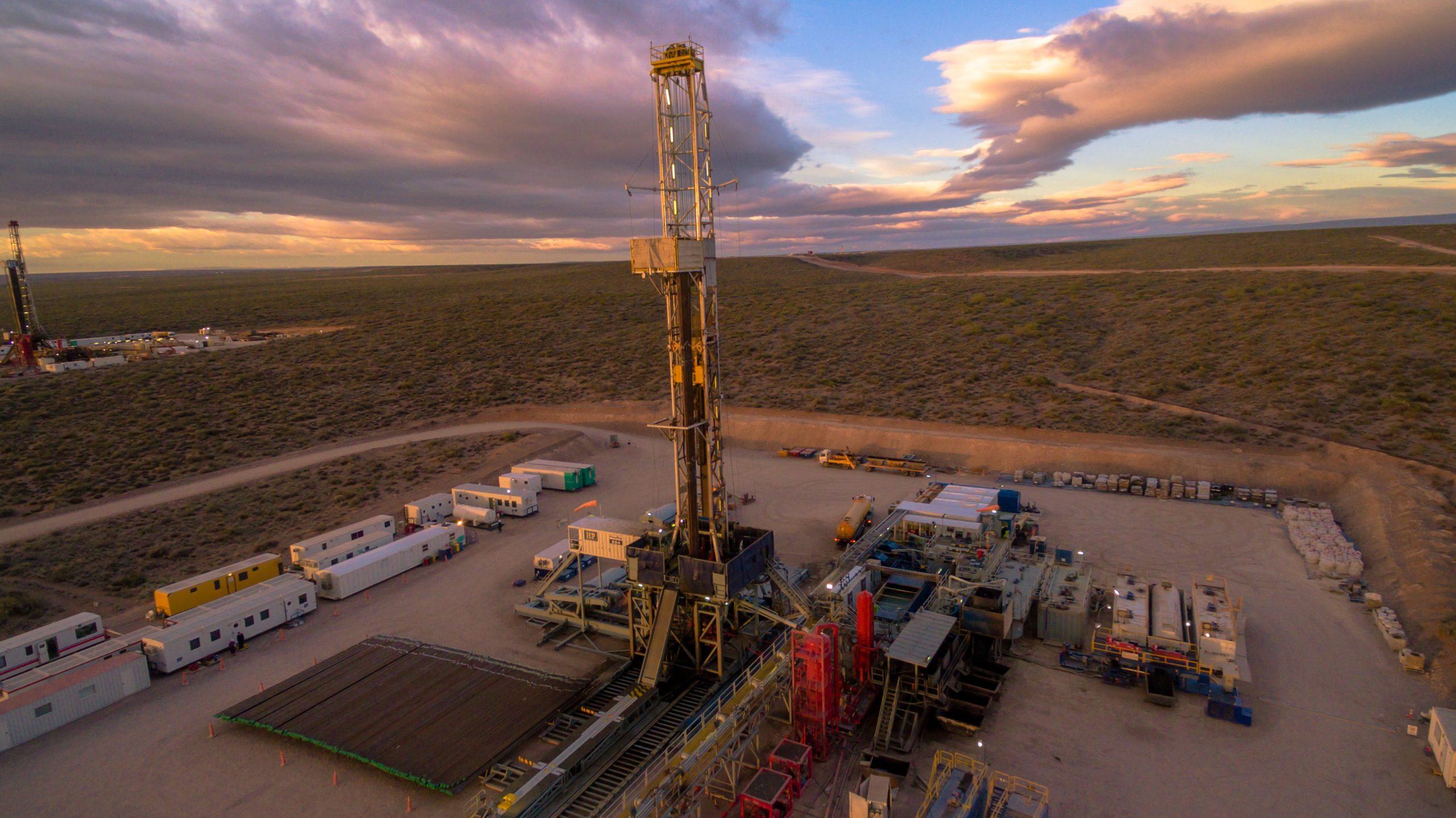

2. Drilling Equipment and Principles

- Rotary drilling fundamentals and rig types

- Power, hoisting, rotation, circulation, and well control systems

- Equipment for high-temperature environments

- Solids control and fluid handling

3. Bottom Hole Assemblies (BHA) and Directional Drilling

- BHA components and configurations

- Mud motors, turbines, and MWD/LWD tools

- Bit types and temperature performance

- Directional drilling design and steering systems

- Temperature limitations in trajectory control

4. Wellbore Surveying and Collision Avoidance

- Survey methods and correction models

- Accuracy and uncertainty in directional wells

- Collision prevention and error models

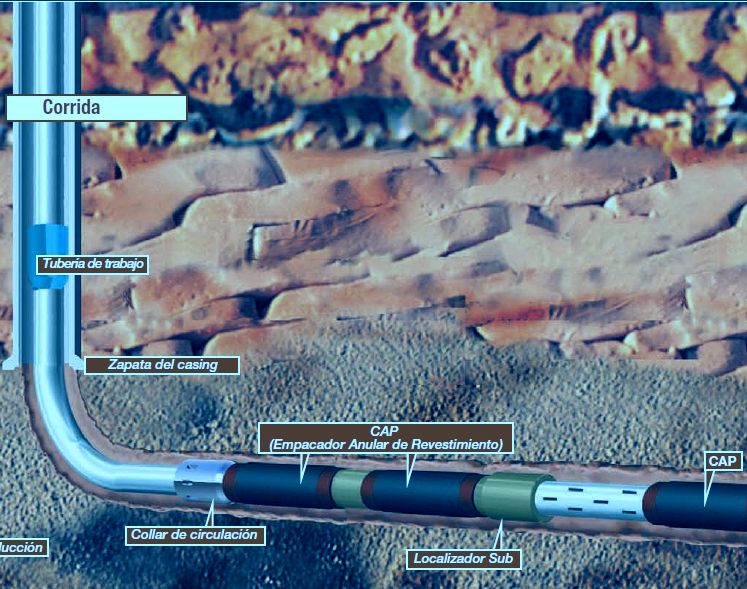

5. Casing and Wellhead Design

- Tubular manufacturing and specifications

- Casing shoe selection and wellhead configuration

- Design considerations for HPHT wells

6. Metallurgy and Material Resistance

- Sweet and sour corrosion

- Selection of alloy materials and cost considerations

- Thermal weakening of tubulars

- Effects of H₂S on material integrity

7. Well Control and Operational Safety

- Hydrostatic pressure principles and kick detection

- Blowout preventers and double-barrier philosophy

- Well integrity and safety procedures

8. Bit Design and Performance

- Bit selection by propulsion method

- PDC cutter design and wear mechanisms

- Diagnosis of bit damage

9. Common Operational Problems

- Pipe sticking and poor hole cleaning

- Torque and drag management

- Axial, lateral, and torsional vibrations

- Fishing techniques and recovery operations

10. Drilling Fluids and Thermal Management

- Types and basic properties of geothermal fluids

- Measurement techniques and temperature effects

- Lost circulation control and safety considerations

11. Applied Geomechanics

- Rock stress analysis: thermal and hydraulic

- Natural and induced fracturing

- ELOT/XLOT test methods

12. Formation Damage and Productivity

- Permeability reduction during drilling

- Strategies to minimize damage and enhance reservoir productivity

13. Regulations, Public Perception, and Innovation

- Regulatory frameworks and licensing

- Risk management, KPIs, and team competencies

- Adoption of new technologies in geothermal drilling