What we do

Training & Talent Management

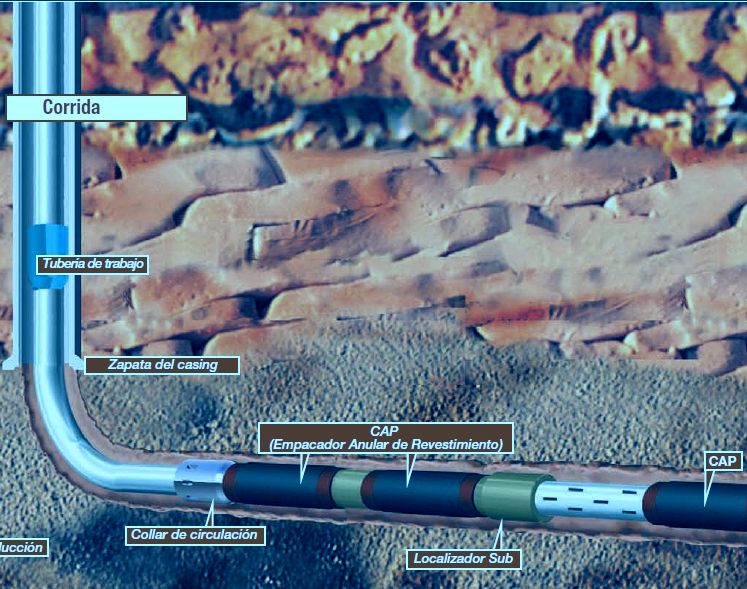

Consulting and Professional Services

- Blog