Objectives:

Participants will learn to design and manage geothermal drilling projects, select appropriate technologies, and handle geothermal-specific risks. The course emphasizes heat transfer, fluid circulation, casing strategies, and safety issues relevant to geothermal energy extraction.

Audience:

This course is designed for drilling engineers, well planners, geothermal project managers, and technical professionals involved in renewable energy development, particularly those transitioning from oil & gas to geothermal operations.

Metodology:

The course is delivered through live online sessions combining instructor-led presentations, interactive discussions, and real-world case studies. Visual aids, schematics, and problem-solving exercises help bridge theory with practice, promoting deep engagement with geothermal-specific content.

Scope:

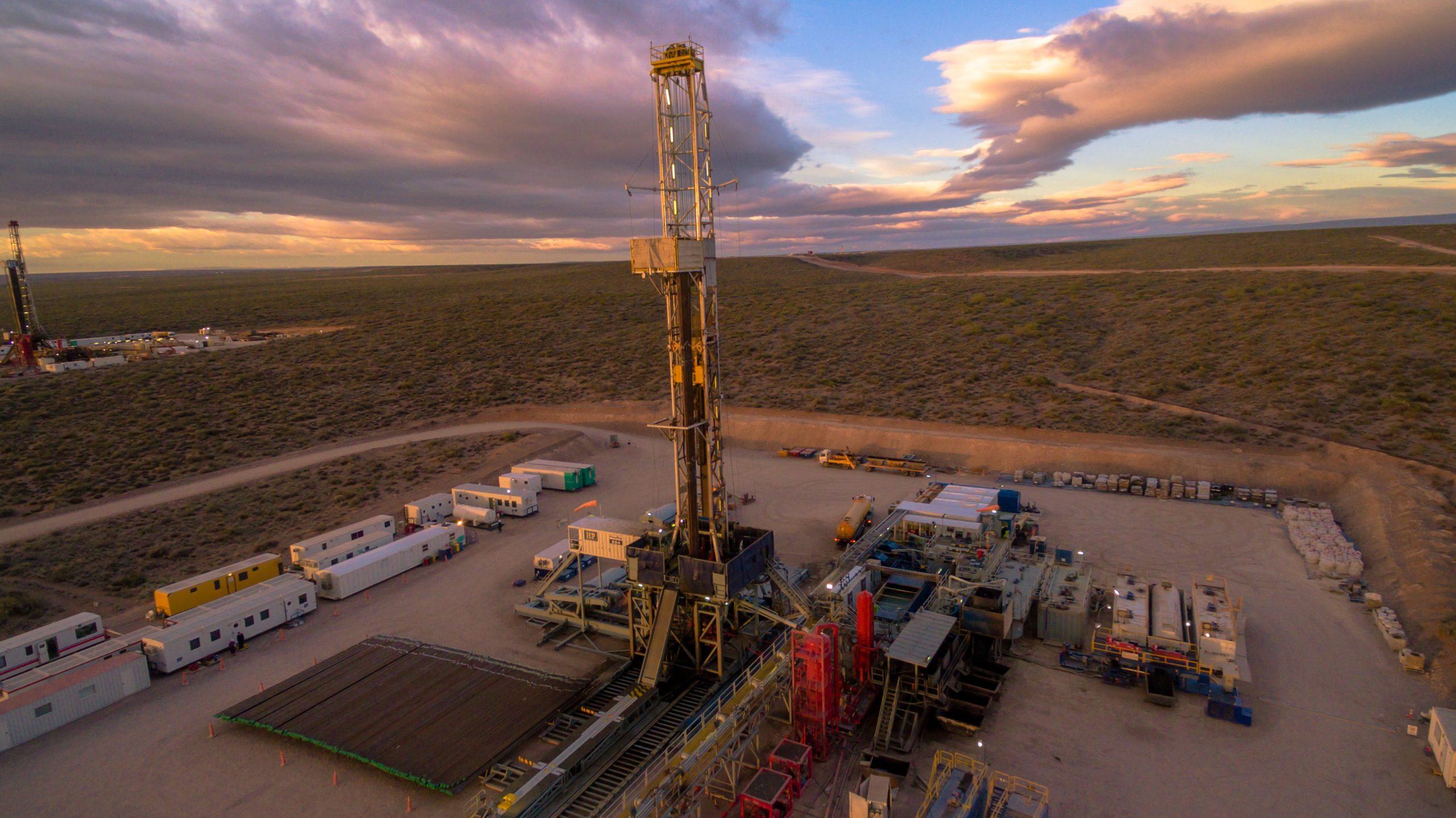

This course explores the unique challenges and technical considerations involved in geothermal drilling operations. It focuses on adapting conventional drilling practices to high-temperature and high-pressure environments, providing an in-depth understanding of the geothermal well construction process.

Content:

1. Introduction to Geothermal Drilling

- Key definitions and concepts

- Types of geothermal wells

- Comparison with oil & gas wells

- Geothermal heat sources and types of exploitation

- Performance gaps and how to evaluate a geothermal resource

2. Drilling Equipment and Principles

- Rotary drilling fundamentals and rig types

- Power, hoisting, rotation, circulation, and well control systems

- Equipment for high-temperature environments

- Solids control and fluid handling

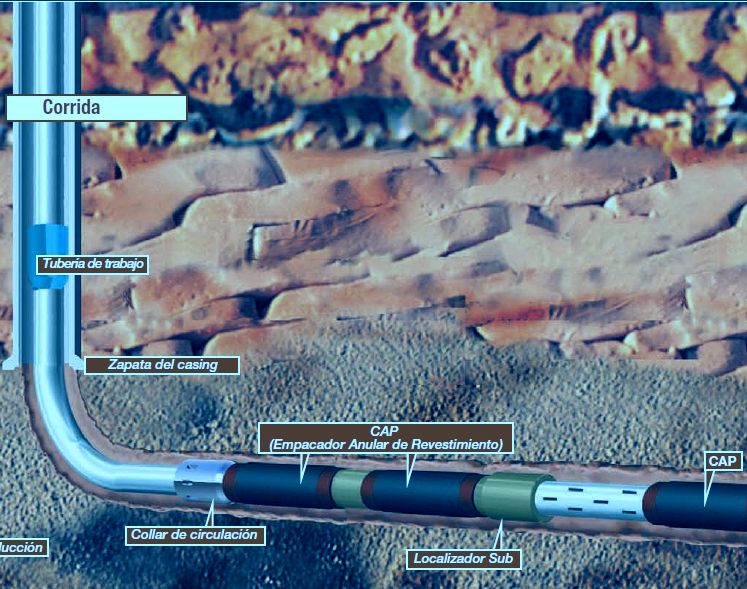

3. Bottom Hole Assemblies (BHA) and Directional Drilling

- BHA components and configurations

- Mud motors, turbines, and MWD/LWD tools

- Bit types and temperature performance

- Directional drilling design and steering systems

- Temperature limitations in trajectory control

4. Wellbore Surveying and Collision Avoidance

- Survey methods and correction models

- Accuracy and uncertainty in directional wells

- Collision prevention and error models

5. Casing and Wellhead Design

- Tubular manufacturing and specifications

- Casing shoe selection and wellhead configuration

- Design considerations for HPHT wells

6. Metallurgy and Material Resistance

- Sweet and sour corrosion

- Selection of alloy materials and cost considerations

- Thermal weakening of tubulars

- Effects of H₂S on material integrity

7. Well Control and Operational Safety

- Hydrostatic pressure principles and kick detection

- Blowout preventers and double-barrier philosophy

- Well integrity and safety procedures

8. Bit Design and Performance

- Bit selection by propulsion method

- PDC cutter design and wear mechanisms

- Diagnosis of bit damage

9. Common Operational Problems

- Pipe sticking and poor hole cleaning

- Torque and drag management

- Axial, lateral, and torsional vibrations

- Fishing techniques and recovery operations

10. Drilling Fluids and Thermal Management

- Types and basic properties of geothermal fluids

- Measurement techniques and temperature effects

- Lost circulation control and safety considerations

11. Applied Geomechanics

- Rock stress analysis: thermal and hydraulic

- Natural and induced fracturing

- ELOT/XLOT test methods

12. Formation Damage and Productivity

- Permeability reduction during drilling

- Strategies to minimize damage and enhance reservoir productivity

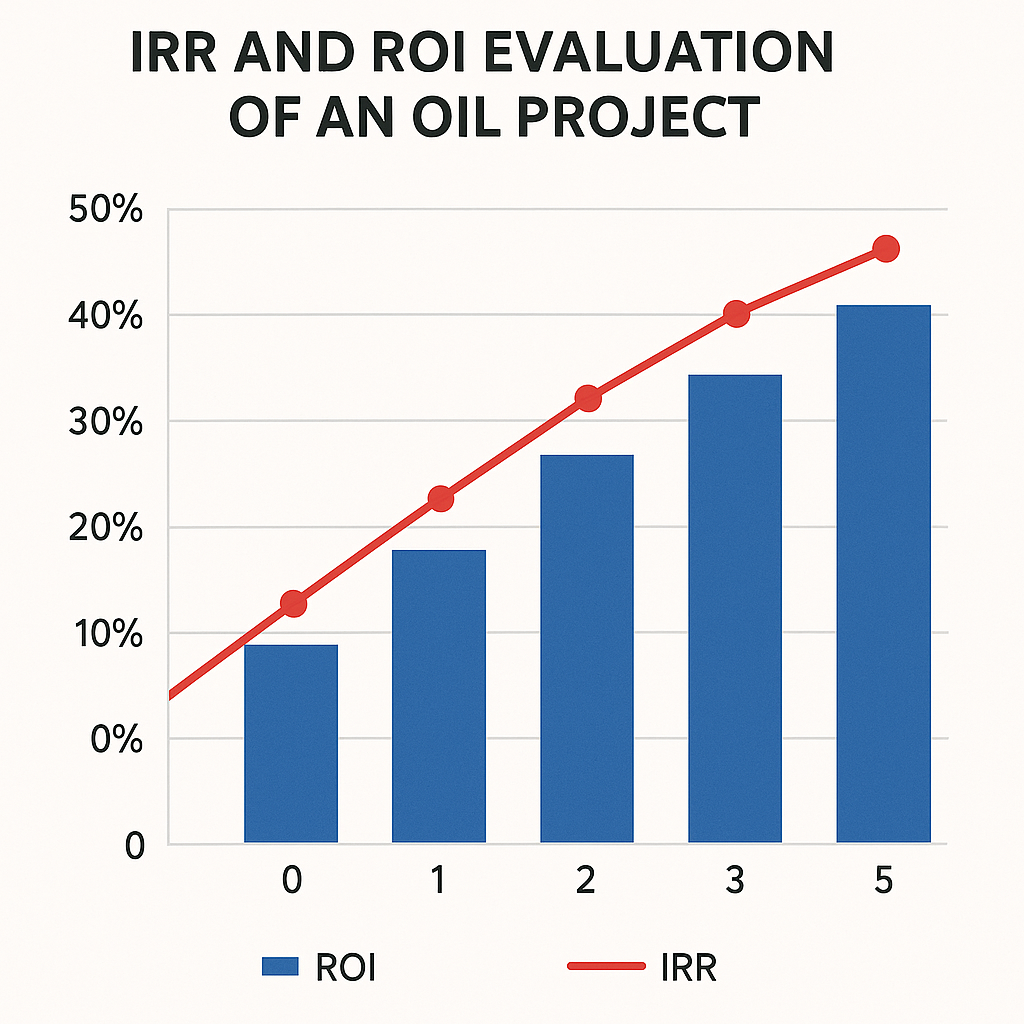

13. Regulations, Public Perception, and Innovation

- Regulatory frameworks and licensing

- Risk management, KPIs, and team competencies

- Adoption of new technologies in geothermal drilling