About Specialized Training Programs (STP)

The Specialized Training Programs (STP) were developed by Bauerberg Klein to provide comprehensive training in each of the areas of E&P, HSE, Maintenance and Soft Skills, based on our educational experience throughout our 17 years of educational experience. The final conformation of each PFE can be adjusted between each program director and the interested Company. They can be conformed within the same discipline or multidisciplinary.

- 1. Prospect Evaluation Risk and Volumes

- 2. Watershed Analysis

- 3. Sedimentology and Tectonics

- 4. Geophysical Exploration Methods

- 5. Geophysical Interpretation

- 6. Seismic and Sequential Stratigraphy

- 7. Clastic and Carbonate Sedimentary Environments

- 8. Exploration Geological Mapping

- 9. Geological and Geophysical Model

- 10. Ajustes de aguas profundas

- 11. Tight and Shale Reservoirs

- PFI Comprehensive Training Programs for Exploration & Production

- 12. Petroleum Systems and Basin Modeling.

- 13. Exploration Petrophysics

- 14. Structural Geology

- Program Director: Rafael Falcón

- Number of modules: 14

- 1. Risk and Volume Assesment

- 2. Sedimentology and Tectonics

- 3. Reservoir Geophysics

- 4. Sequential Stratigraphy

- 5. Clastic and Carbonate Sedimentary Environments

- 6. Sedimentary Modeling and Sequence Stratigraphy

- 7. Static Reservoir Model

- 8. Subsurface Geological Mapping

- 9. Structural Styles

- 10. Operations Geology

- 11. Interpretation of Profiles

- 12. Petrophysical Evaluation of Chlastic and Carbonate Reservoirs

- 13. Production Geology

- Program Director: Rafael Falcón

- Number of modules: 13

- 1. Introduction to Reservoir Engineering

- 2. Introduction to Stimulation, Completions and Workovers

- 3.Reserves Calculation Workshop

- 4. Seismic for Engineers and Geologists (Non-Geophysicists)

- 5. Reservoir Engineering (Intermediate)

- 6. Water Control

- 7. Hydrocarbon Properties (PVT-EOS)

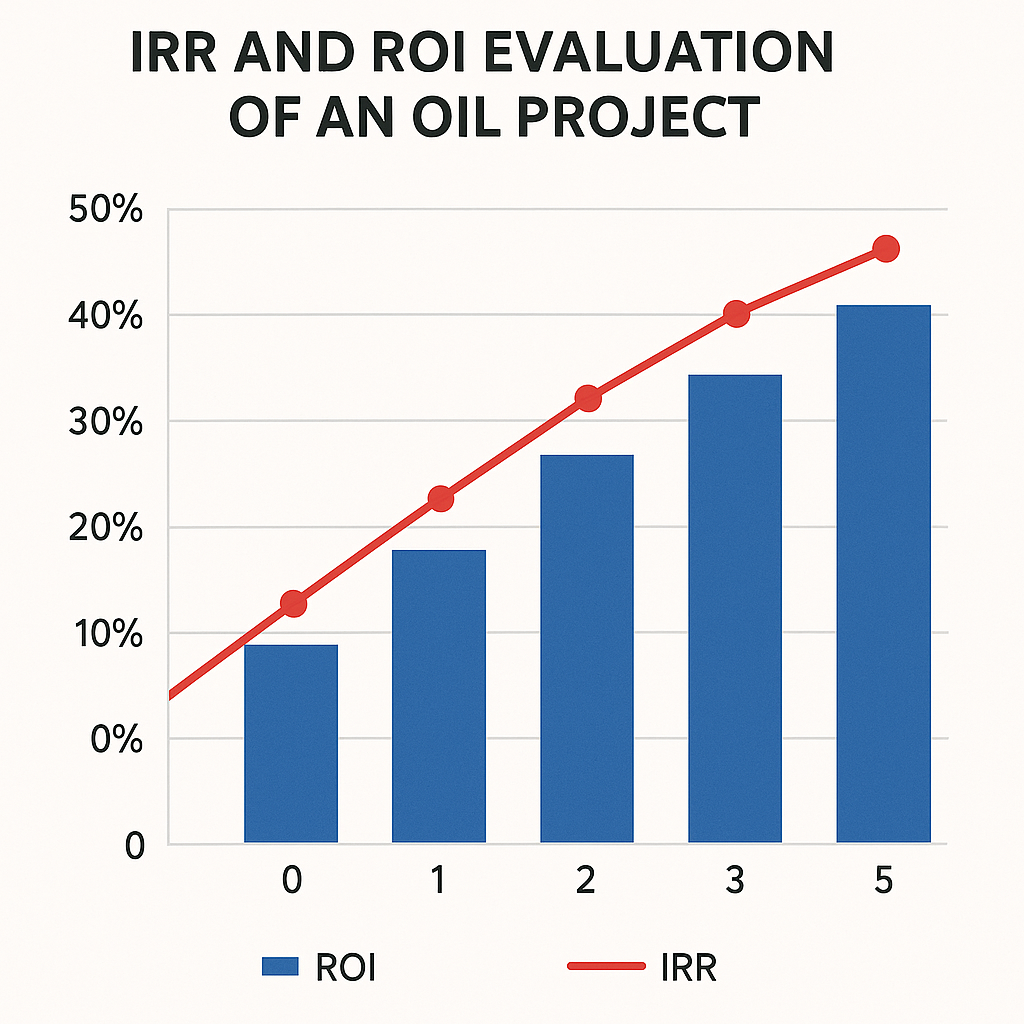

- 8. Project Evaluation

- 9. Well Testing

- 10. Formation Evaluation (Petrophysics)

- 11. Enhanced Recovery Methods (EOR)

- 12. Waterflooding

- 13. Reservoir Simulation

- Program Director: Marcelo Reyna

- Number of modules: 13

- 1. Introduction to Production Engineering

- 2. PVT Hydrocarbon Properties

- 3. Nodal Analysis

- 4. Artificial Lift Systems

- 5. Mechanical Pumping

- 6.Submersible Electro Pumping (BES)

- 7. Gas Lift

- 8. Progressive Cavity Pumping (PCP)

- 9. Introduction to Stimulation

- 10. Waterflooding Surveillance

- 11. Completions & Workovers

- 12. Surface Facilities

- Program Director: Richard Márquez

- Number of modules: 12

- 1. Drilling Fluids and Solids Control

- 2.Drill String Design

- 3. Drill Bit Selection and Evaluation

- 4. Drilling Hydraulics

- 5. Settling Points and API Design of Liners

- 6. Primary Cementation

- 7. Electrical Records

- 8. Well Completions and Workovers

- 9. Drill Planning and Selection

- 10. Pipe Bonding

- 11. Directional Drilling

- 12. Influence Prevention and Well Control

- 13. Drilling Plan Development Project

- Program Director: Jairo Molero

- Number of moduels: 13

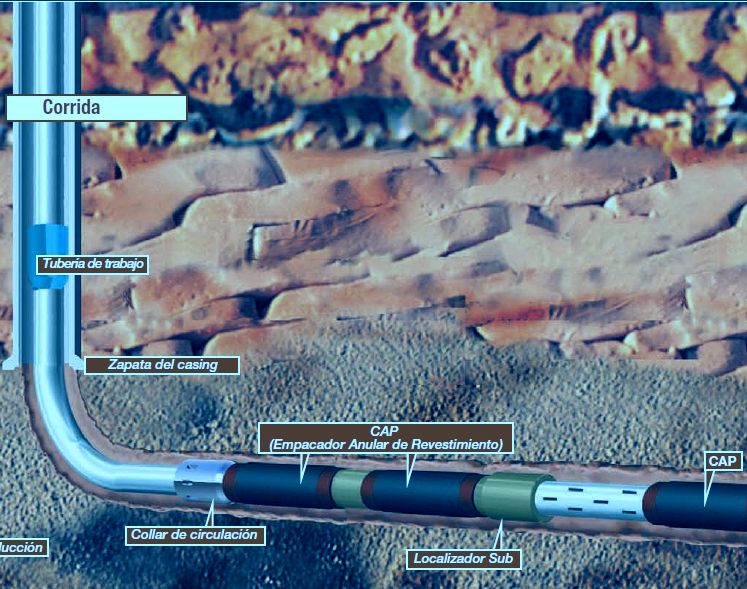

- 1. Completions & Workovers

- 2. Completion and Workover Fluids

- 3. Remedial Cementation (Squeeze)

- 4. Training Damage

- 5. Matrix Acid Stimulation

- 6. Hydraulic Fracturing

- 7. Horizontal and Multilateral Well Completions

- 8. Sand Control

- 9. Coiled Tubing Operations

- 10. Pulling Operations

- 11. Slick Line and Wire Line operations

- 12. Introduction to Offshore Operations

- Program Director: Carlos Álvarez e Ignacio Martinez

- Number of modules: 12

- 1. Surface Facilities

- 2. Fluid Properties

- 3. Oil and Gas Processing

- 4. Gas Processing

- 5. Petroleum Processing

- 6. Training Water Treatment

- 7. Corrosion

- 8. Gas Transportation

- 9. Petroleum Transportation

- 10. Surface Installation Projects

- 11. Process Control in Reservoir Facilities

- Program Director: Freddy Ordosgoytti

- Number of modules: 11

- Value of Each Module: USD 3.900

- Total value of the PFI: USD 42.900

- 1. Risk-based Process Safety (RBPSM)

- 2. Hazop. What If?

- 3. ATEX and Hazardous Area Classification

- 4. Electrical Safety in Drilling and Workover Equipment

- 5. Behavioral Safety

- 6. Accident Investigation

- 7. Occupational Health and Safety Management System – ISO 45001 Standard

- 8. Environmental Impact

- 9. Energy Transition

- 10. Environmental Management Systems according to ISO 14001

- 11. Emergency Management

- 12. Spill Control

- 13. Fire Control

- Program Director: Amalia Mendoza

- Number of modules: 13

- 1. Maintenance Planning and Scheduling

- 2. Maintenance management and its measurement through kpi’s.

- 3. Reliability Centered Maintenance (CQM)

- 4. Introduction to operational reliability

- 5. Process mapping (administrative and operational)

- 6. ISO 55001 Asset Management Fundamentals

- 7. Integration of maintenance with asset management (EN-14646)

- 8. Application of the ISO-14224 standard in data management

- 9.Criticality Analysis (CA)

- 10.Root Cause Analysis (RCA)

- 11. Inspection Based on Risk (IBR)

- 12. Mechanical integrity

- Program Director: Jorge Omaña

- Number of modules: 12

- 1. Communication for decision making

- 2.Management of roles and responsibilities in the work teams.

- 3. Corporate Leadership and Delegation

- 4. Effective leadership and coordination

- 5. Emotional Intelligence in Business Effectiveness

- 6. Strategic uses of power in organizations

- 7. Learning habits in work teams

- 8. Workflow and Productivity of work teams

- 9. Team Building for project management

- 10. Alignment of the work teams with the corporate strategy

- 11. The role of Internal Consulting in organizations

- 12.Coordination skills among specialists

- 13. Internal Mentoring Skills in Organizations

- 14. Human reliability

- Program Director: Ricardo Palma

- Number of modules: 14

MORE INFORMATION

Duration of modules

From 8 to 20 hours in sessions of 3.5 to 4 hours per day.

Students per module

Up to 15 participants

Instructors and Program Directors

All instructors who are part of the PFEs have extensive experience and academic training.

The Directors of each Program and the General Coordinator, together with the technical referents and HR personnel of the Contracting Company will be in charge of adapting the contents of the modules (approach, duration and methodologies to be applied, etc.), taking into account their specific needs and possibilities. They will also monitor the development of the modules, and will prepare a technical report together with the instructors, after each module carried out, which may contain academic recommendations, and will prepare a final report at the end of the PFE.

Blended Learning

Synchronous E-Learning 80% – To be complemented with Asynchronous E-Learning, Complementary Readings and Exercises.

Presenciality

At the Client’s request, all or some of the modules may be carried out in person.

Recommended time to complete each PFE

From 12 to 18 Months

Examinations and Report for HR

In all modules a detailed report will be made on the topics covered, class participation, student grades, course satisfaction rating.

Academic Level

Although the levels of each module are designed as basic or intermediate, they can be adapted to be taken by participants of more advanced levels.

Customized PFE modules

The contents of each module can be adjusted through meetings with HR and the technical line with Bauerberg Klein instructors.

Customized PFE

PFIs can be structured according to the training needs of each company.

Interdisciplinary IPP can also be carried out.